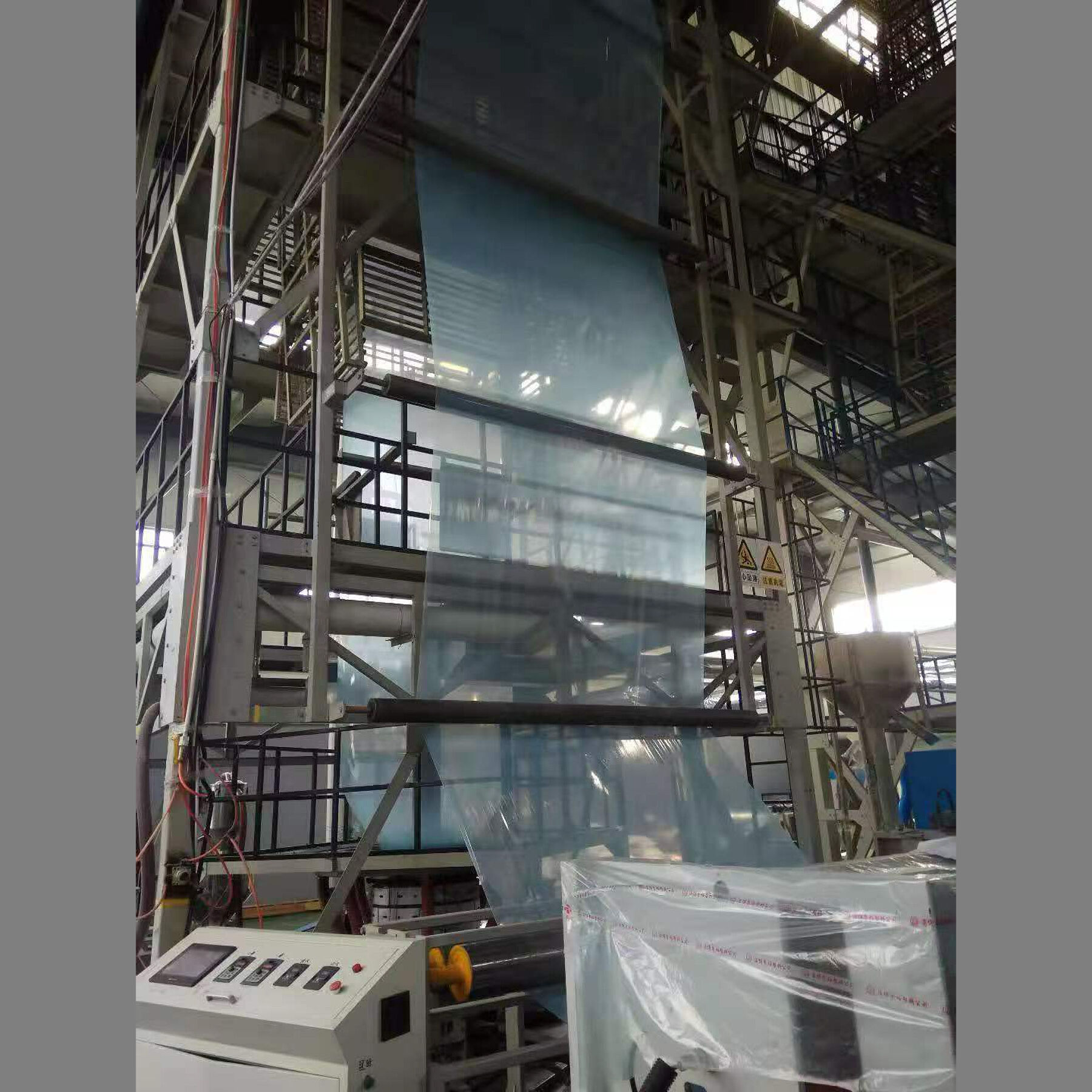

The plastic film blowing machine is one of the manufacturing equipment that serves as means of production of plastic film which is done by extrusion of plastic and blowing it. The working mechanism of this machine involves melting of plastic chips and converting them into cylindrical billets that are subsequently blown up into membranes. Such membranes are increasingly used in packaging materials, in agriculture and many other sectors which necessitates their high quality production. At Caihua Rubber & Plastic Machinery Co., Ltd, we concentrate on development and high standards of production, so our machines correspond with the worldwide requirements and will meet the needs of different clients worldwide.

ONLINE

ONLINE