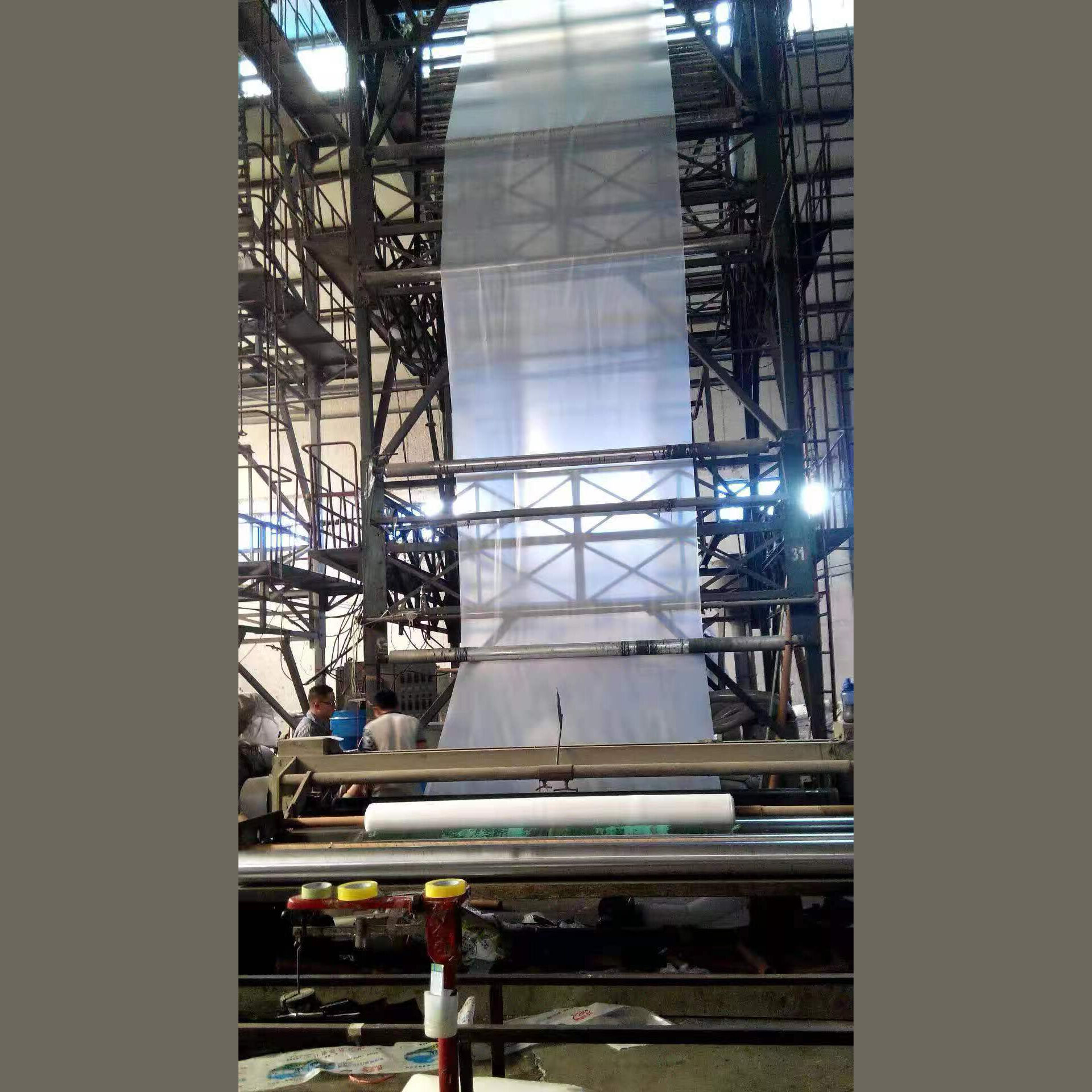

The single layer and multi layer film blowing processes are crucial for the manufacturing of flexible film packaging. Because they are used only in simple applications, single layer films are often less complicated and less expensive. On the other hand, multi layer films are constructed from more than one material which is meant to improve certain characteristics like strength, barrier properties and thermal stability. This enables manufacturers to produce more targeted products, for instance some suitable for food preservation or industrial packaging. As Caihua has good experience in both technologies, we are able to offer bespoke solutions to our clients that enhance their innovation and efficiency.

ONLINE

ONLINE